Automation control systems, or in short, automation, were born and applied in many different occupations in today’s society and especially in the industrial production industry. There have been many articles talking about the benefits of industrial automation. However, these are all general benefits. Through the process of designing hundreds of automatic machine projects for supporting manufacturing industries, VCC has realized many benefits from practical automation.

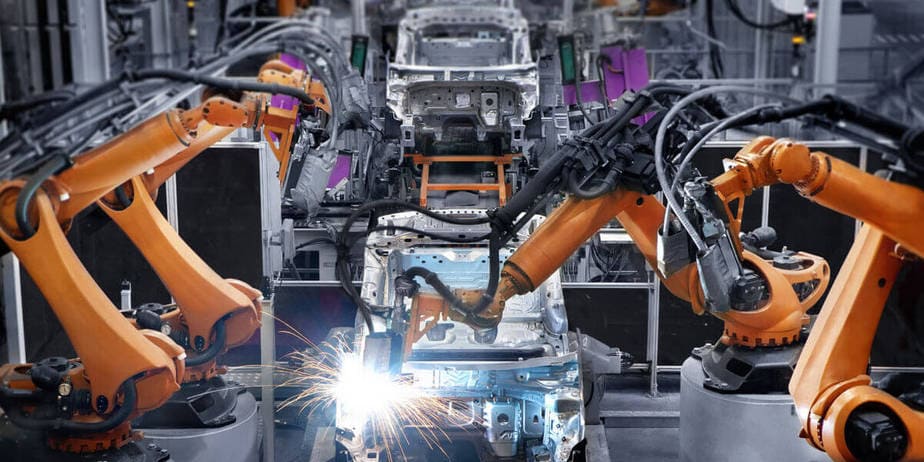

In the field of industrial production, a lot of human resources and technology are needed because the production of goods requires high precision, speed and stability. The resulting automation control system helps solve many problems in manufacturing and other industries. We can take a look at some of the benefits that automation has brought.

- Increase productivity: Manufacturing factories always have measures to divide shifts and usually have 2 to 3 shifts to ensure progress and continuous operation of machines, but even if such shifts are divided, it will still There is time off between shifts, problems require machine repair, and production operations will still have downtime. But when applying automation, the production line will ensure that the operating process takes place continuously and moreover, the operating speed of machines is always faster than manual human operations and that is is still the top and most obvious benefit when factories apply automation control systems.

- Quality improvement: Automation significantly reduces human-related errors. Unlike human workers, robots do not tire, which leads to uniformity in production quality at any given time.

- Cutting labor costs: The application of automation will limit the use of many workers for a production process, thereby minimizing labor costs, and there will be an investment cost. Adding automated machinery and equipment will be better and more efficient.

- High customization: Changing the production process, especially when adding new steps, is often very complex, as it must be accompanied by worker training and management changes. For robots, the program will ensure the ability to do all assigned tasks. This will increase customization in production.

- Highly accurate information collected: Automatic information collection can assist businesses in obtaining important information from production, increasing data accuracy and cutting collection costs collect data. Businesses that apply this feature well can create breakthroughs in business, thanks to the ability to make the right decisions at the right time, as well as the ability to cut waste and optimize processes. submit.

- Labor safety: With harsh production environments, implementing automated lines will ensure human safety.

- Improving worker qualifications: Applying modern scientific techniques to the production process also requires people to improve their qualifications to be able to operate and control machines. From there, the qualifications of workers will be improved and developed to be able to adapt to modern technologies.